While traditional lithium-ion batteries have powered the first wave of electric vehicles, recent breakthroughs in solid-state and alternative chemistry technologies are redefining what’s possible in the automotive sector. The energy density of solid-state batteries now reaches an impressive 300-500 Wh/kg, enabling vehicles to travel over 1,000 kilometers on a single charge. These batteries utilize non-flammable electrolytes, virtually eliminating the risk of thermal runaway that has plagued conventional lithium-ion cells. The durability metrics are equally striking, with cycle life extending to 8,000-10,000 cycles—a significant leap forward for long-term ownership economics.

Solid-state battery breakthroughs have supercharged EVs with 300-500 Wh/kg density, enabling 1,000km range and exceptional durability.

Fast-charging capabilities have evolved remarkably, with current technologies delivering 80% charge in just 15 minutes. The Porsche Taycan exemplifies this progress, achieving 100 km of range in a mere 5.5 minutes when connected to 800-volt infrastructure. I’ve examined numerous charging networks, and Tesla’s Supercharger remains the benchmark for practical long-distance EV travel, though competitors are closing the gap rapidly. Toyota’s innovative solid-state batteries using sulfide superionic conductors promise to reduce charging times to just seven minutes, further alleviating consumer concerns about EV practicality. The Battery Show and EV Tech Expo 2025 featured impressive on-board chargers designed specifically for these higher voltage systems.

Alternative chemistries represent another frontier in battery development. Sodium-ion batteries cost approximately half as much as lithium-ion equivalents while boasting theoretical lifespans exceeding 3,000,000 miles. These solutions reduce dependence on scarce materials like cobalt, addressing critical supply chain vulnerabilities. Silicon anodes deliver capacities approaching 4,200 mAh/g, dwarfing graphite’s 372 mAh/g ceiling and dramatically boosting potential range. Modern EV batteries can function effectively for 15-20 years or up to 280,000 miles before requiring replacement, significantly extending vehicle usability.

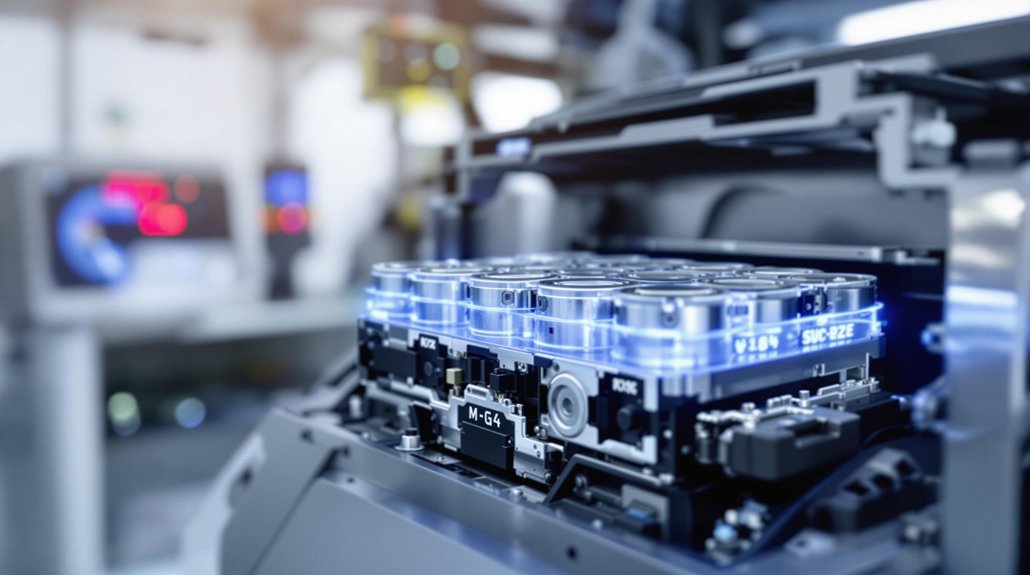

China has emerged as the leader in solid-state battery production, establishing robust supply chains for scaled manufacturing. Flexible polymer electrolytes have solved previous assembly challenges, making high-volume production feasible for automotive applications.

Industry projections suggest global EV revenue will reach $561.4 billion by 2025, driven largely by these battery innovations.

The environmental implications are substantial, with advanced recycling processes now capable of recovering critical materials from end-of-life batteries. This circular approach, combined with the shift toward abundant elements like sodium, positions the EV industry for sustainable growth as adoption accelerates worldwide.