Sweden’s emergence as a powerhouse in electric vehicle battery production represents one of Europe’s most strategic industrial developments of the decade. With Northvolt targeting 32 GWh annual production by 2023 and Lyten’s acquisition adding 16 GWh existing capacity plus 15 GWh under construction, the Nordic nation is positioning itself as a formidable competitor to Asian manufacturers. The scalability to 100+ GWh demonstrates an ambition that matches Europe’s urgent need for energy independence.

Sweden emerges as Europe’s battery frontier, challenging Asian dominance with ambitious production targets and strategic industrial foresight.

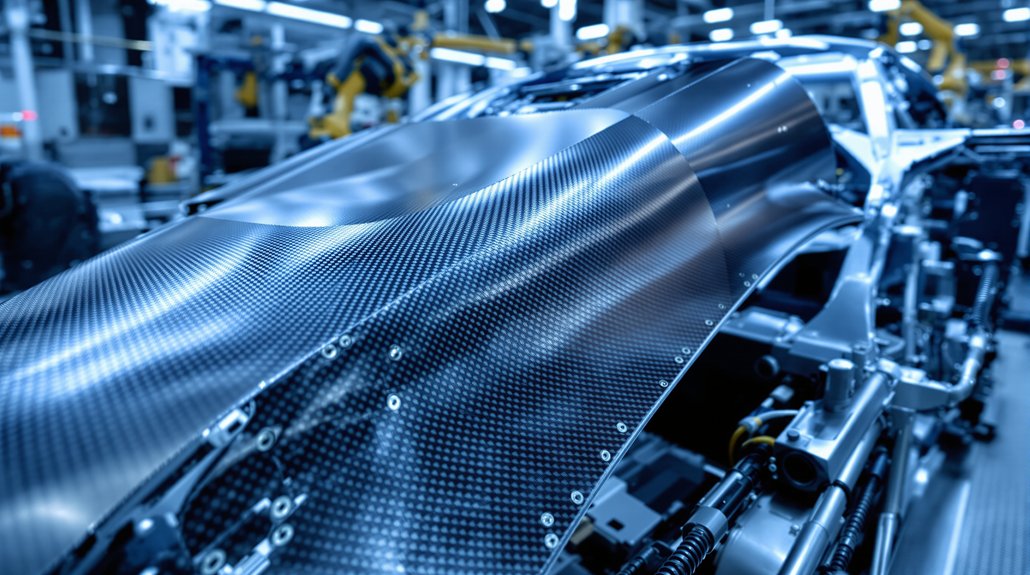

The technical superiority of Swedish batteries stems largely from groundbreaking structural battery technology developed at Chalmers University. These innovations integrate energy storage directly with load-bearing components, potentially increasing EV range by a remarkable 70%. I’ve examined similar concepts previously, but none achieved the 30 Wh/kg energy density while maintaining aluminum-like stiffness through carbon fiber composites.

Safety advances cannot be overstated in the Swedish approach. By embedding batteries within carbon fiber-reinforced structures, these designs inherently resist crash damage more effectively than conventional lithium-ion packs. The reduced heavy metal content—particularly less cobalt and more locally-sourced graphite and nickel—mitigates both environmental impact and thermal runaway risks. Lyten’s focus on lithium-sulfur batteries also contributes to safety improvements due to the energy independence needs driving innovation in this area.

Manufacturing efficiency benefits from an impressive concentration of expertise, with executives hailing from Tesla, Renault Nissan, and BASF Toda Battery Materials. The co-location of R&D with production facilities enables an agility in development that most battery manufacturers would envy. The leadership team led by former Tesla executive Peter Carlsson brings invaluable industry experience to Northvolt’s ambitious projects.

Sustainability runs through the entire Swedish battery ecosystem. Hydroelectric power drives production, while facilities are designed from the ground up for recycling capabilities. This circular approach, when paired with the structural advantages, creates what might be the world’s most environmentally responsible battery technology. Swedish manufacturers are embracing second-life applications to extend battery utility beyond their primary automotive use.

European automakers have taken notice. The combination of advanced technology, sustainability credentials, and proximity to assembly plants makes Swedish batteries increasingly attractive as the continent pushes toward electrification. The days of complete dependence on Asian battery imports appear to be waning, with Sweden leading Europe’s charge toward energy self-sufficiency.