The global electric vehicle battery recycling market surges forward, transforming what was once an afterthought into a cornerstone of automotive sustainability. Projected growth from $4.81 billion in 2024 to a staggering $73.18 billion by 2034 represents a paradigm shift in how the automotive industry approaches resource management. Britain stands at the crossroads of this revolution, positioned to capitalize on Europe’s leading market share while contributing to the 27% compound annual growth rate that defines this sector.

The regulatory landscape has evolved dramatically, with stringent recycling mandates now commonplace across developed markets. European requirements of 75% recovery for nickel-cadmium batteries and 50% for other chemistries set a high bar that drives innovation. New targets for recycled content—16% cobalt and 6% lithium by 2031, increasing to 26% and 12% respectively by 2036—create a clear roadmap for manufacturers. The implementation of Extended Producer Responsibility policies is forcing manufacturers to take accountability for the entire lifecycle of their batteries.

Evolving regulations drive unprecedented innovation, establishing ambitious recovery targets that redefine sustainability in battery manufacturing

I’ve observed these regulations catalyzing unprecedented cooperation between previously siloed industries.

Technological breakthroughs have made this shift economically viable. Hydrometallurgical processes now separate high-purity metals from black mass with remarkable efficiency, while pyrometallurgy recovers valuable cobalt, nickel, and copper. The rise of lithium-iron-phosphate batteries in lower-cost EVs is creating new challenges and opportunities for recyclers focused primarily on lithium and graphite recovery. The emergence of direct upcycling techniques preserves cathode materials without reduction to base elements, slashing both energy consumption and processing costs. These innovations are particularly critical as extreme weather can permanently damage batteries and reduce their usable lifespan.

Environmental benefits extend beyond mere compliance. By reducing dependence on newly mined lithium, cobalt, and nickel, recycling greatly cuts carbon emissions while preventing hazardous waste from entering landfills. Recovery rates approaching 99% for lead demonstrate what’s possible when industry commits to circular principles.

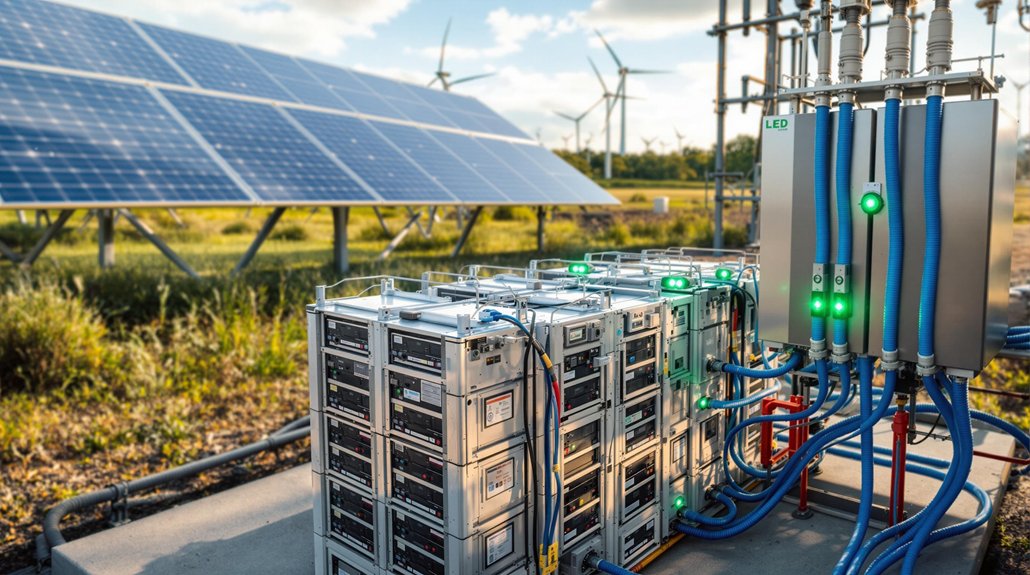

Commercial developments signal market maturation, with major recyclers scaling operations to handle the coming wave of end-of-life EV packs expected in the late 2020s. Corporate investments in regional recycling facilities across Britain create localized circular ecosystems, strengthening supply chain resilience.

The collaboration between waste management specialists and automakers establishes the infrastructure necessary for sustainable growth in Britain’s electric vehicle sector, redefining what’s possible when innovation meets necessity.