Efficiency stands at the forefront of modern automotive innovation, and regenerative braking technology represents one of its most elegant implementations. This ingenious system transforms what would otherwise be wasted energy during deceleration into valuable electrical power, creating a cyclical energy flow that considerably enhances vehicle performance. Unlike conventional friction brakes that convert kinetic energy into heat, regenerative systems capture this energy and redirect it to the vehicle’s electrical storage system.

Regenerative braking elegantly transforms wasted energy into electrical power, creating a sustainable cycle that revolutionizes vehicle efficiency.

The working principle relies on the dual nature of electric motors. During deceleration, these motors reverse their operational mode, functioning as generators rather than propulsion devices. As the vehicle slows, the motor harvests kinetic energy and converts it to electricity, which is then routed to batteries or capacitors for storage. The process activates automatically when drivers lift off the accelerator, apply brake pressure, or navigate downhill sections, creating seamless energy recovery. Regenerative braking’s effectiveness notably decreases at lower speeds, requiring supplemental friction braking for complete stops.

Primarily deployed in electric and hybrid vehicles, regenerative braking has revolutionized energy management in modern transport. I’ve observed that fully electric vehicles benefit most profoundly, with regenerative systems recapturing up to 70% of energy during braking events. This recaptured energy directly contributes to extended driving range, a critical factor in EV adoption. Early implementations of this technology were found in trolley cars, showcasing its long-standing viability.

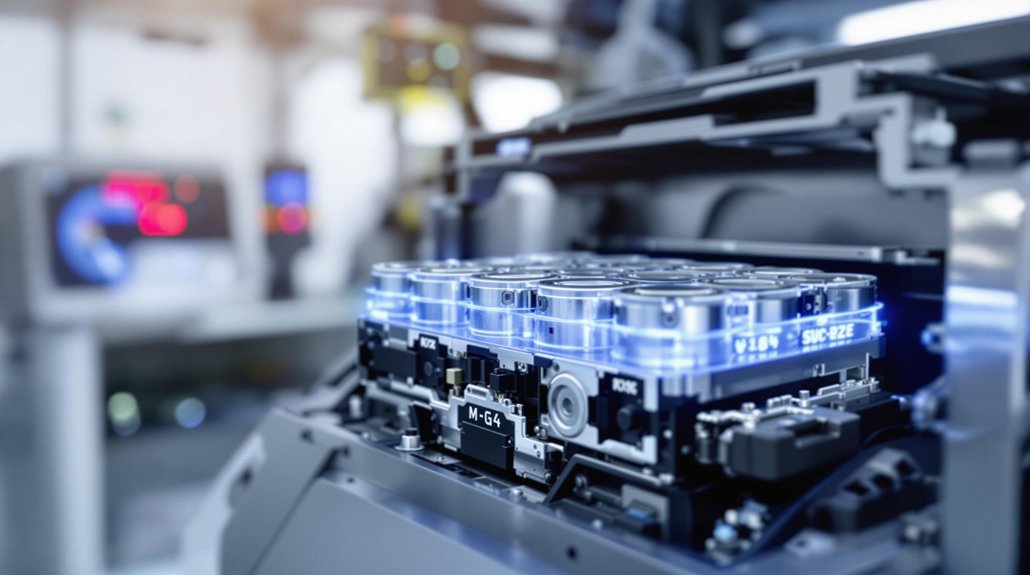

Beyond efficiency gains, these systems deliver notable secondary benefits. Traditional brake components experience reduced wear, with many EV owners reporting brake pad lifespans exceeding 100,000 miles—approximately double that of conventional vehicles. The implementation requires sophisticated control systems that manage the shift between propulsion and generation modes, balancing regenerative and friction braking for peak performance. Modern regenerative braking systems incorporate advanced thermal management to prevent energy density loss during rapid charging cycles, similar to innovations seen in charging technologies.

The technology represents a fundamental shift in how vehicles manage energy. Rather than constantly consuming power, modern electric and hybrid vehicles create an ecosystem of energy utilization, where deceleration phases contribute to future acceleration.

This regenerative approach exemplifies automotive engineering‘s evolution from linear consumption models to circular systems that maximize efficiency at every stage of vehicle operation.